The aerospace industry is the largest user of titanium products. It is a useful material for this industry because of its high strength to weight ratio and high temperature properties. Titanium is typically used for airplane parts and fasteners. These same properties make titanium useful for the production of gas turbine engines while it is also used for other parts such as the compressor blades, casings, engine cowlings and heat shields.

The aerospace industry is the largest user of titanium products. It is a useful material for this industry because of its high strength to weight ratio and high temperature properties. Titanium is typically used for airplane parts and fasteners. These same properties make titanium useful for the production of gas turbine engines while it is also used for other parts such as the compressor blades, casings, engine cowlings and heat shields.- The expansion in use of titanium within the aerospace market can be attributed to several factors, including the demand for newer aircraft designs with increased CFRP (carbon fiber reinforced polymer [or plastic]) composition. By sharing the same thermal expansion rates as many popular composite materials, titanium is highly favored as a composite interface material.

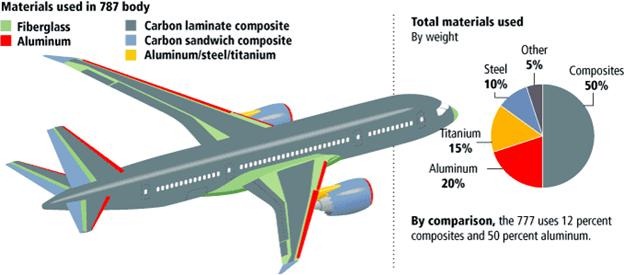

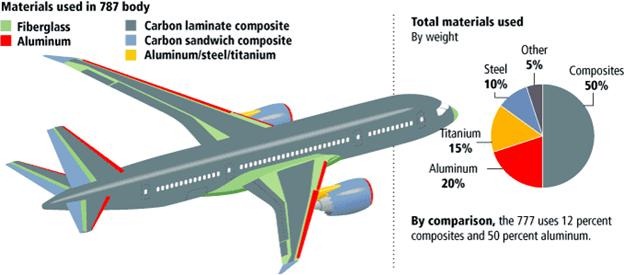

- The new Boeing 787 Dreamliner is estimated to use 15 percent titanium by weight, 5 percent more thansteel and is surely the exemplar for the increased use of titanium in commercial aircraft manufacturing. Increased titanium use in this aircraft directly corresponds with that of composite components based on the materials’ compatibility. The rise in composite design, construction and use is a strong indicator of additional increases in titanium part production.

- Current industry projections for titanium indicate a 40 percent increase in demand by 2015. Anticipating this growth, many major producers of titanium have announced plans to increase their production capacities.

The aerospace industry is the largest user of titanium products. It is a useful material for this industry because of its high strength to weight ratio and high temperature properties. Titanium is typically used for airplane parts and fasteners. These same properties make titanium useful for the production of gas turbine engines while it is also used for other parts such as the compressor blades, casings, engine cowlings and heat shields.

The aerospace industry is the largest user of titanium products. It is a useful material for this industry because of its high strength to weight ratio and high temperature properties. Titanium is typically used for airplane parts and fasteners. These same properties make titanium useful for the production of gas turbine engines while it is also used for other parts such as the compressor blades, casings, engine cowlings and heat shields.